Welding Filters: Basic Functioning And Importance

Welding is a key part of metal fabrication. Apart from the complicated nature of the process, it can also be quite harmful to the welder and surrounding technicians. The main culprit is the toxic fumes that emanate during welding. To mitigate this, many manufacturers and shop floors use a welding filter which is a form of a fume extractor. In this blog, Dynamic Filtration Ltd., manufacturers of industrial filters, explore the basics of this welding filter and why it serves an important purpose.

What Is A Welding Filter?

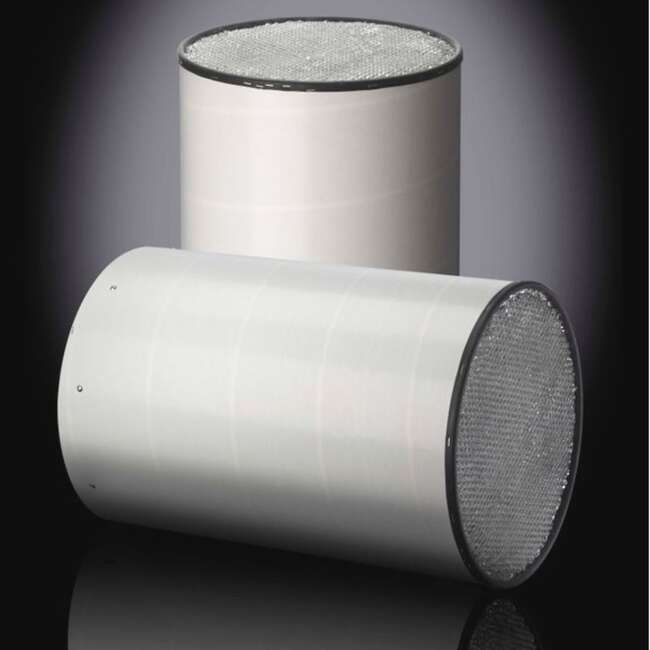

A welding filter is a form of filtration device that removes the fumes generated during the welding and machining process in an industrial setting. It uses one or multiple filters in conjunction to create effective filtration. Some of the most common types of filters used include:

- Pre-Filter: Before entering the main filter, the larger fume particles and other contaminants are captured by this pre-filter.

- Main Filter: Comprising the main filter element such as paper or polyester, this filter is responsible for removing the vast majority of contaminants generated due to welding.

- After Filter: To address any smaller lingering particles, the after filter is used to ensure clean, breathable air.

- HEPA Filter: Although not absolutely necessary, HEPA filters will ensure even the tiniest of toxic particles are eradicated from the air.

Importance Of Welding Filters

Welding filters remove toxic fumes and gases generated during the welding process. This is critical because:

- These fumes can cause respiratory issues through long-term exposure.

- Some are even carcinogenic in nature. Hence, they must be eliminated at all costs.

Therefore, welding filters are a staple in the metal fabrication sector and are quite effective in removing almost all toxic particles arising from the fumes. To know more about welding filters and other types of industrial filters, please reach out to us at Dynamic Filtration Ltd. today. With more than 3 decades of experience, the company strives to build the highest-quality filters that are durable and easy to maintain. Contact us today at 519-886-0749 to learn more or to request a quote.