3 Tips To Properly Install Pleated Air Filters

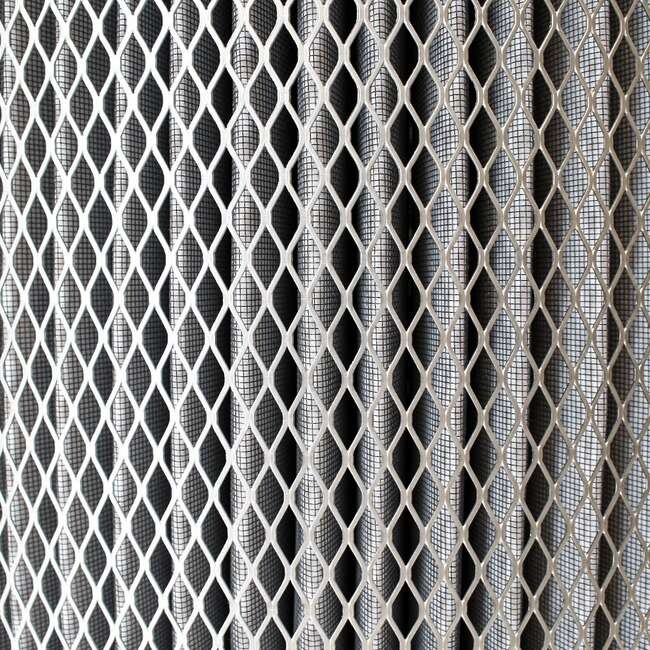

Pleated filters are a reliable form of air filtration for industrial settings. The large surface area of the industrial filter makes it easy to remove contaminants from the air system. However, be it going for a custom filter or a regular one, installing pleated filters can be a challenge. Here are 3 tips to avoid any errors or pitfalls while installing pleated air filters.

How To Install Pleated Air Filters?

Ensure The Dimensions Are Correct

The first step is to ensure that the pleated air filter is the right size for a particular housing and application. This becomes even more important for custom filters, as their dimensions can be altered. Failing to follow this leads to major challenges during the installation process, resulting in leakage of air and bringing down the overall quality of the industrial filter.

Ensure The Pleats Are Facing The Correct Way

This is a relatively simple but important aspect of pleated filter installation. Always make sure that the pleats of the filter are facing downwards. If it is facing the wrong direction, it will result in a restriction of airflow and will have to be reinstalled.

Choose Professional Technicians For Installation

The best course of action is to go for a professional technician or installation crew who is well-versed in the process of setting up pleated filters. They have the right knowledge and necessary tools to carry out the installation process smoothly without a hitch.

At the end of the day, irrespective of the type of filter, proper installation and maintenance are essential for optimal performance and longevity.

For pleated filters or other types of specialized filters, look no further than Dynamic Filtration Ltd. Home to different types of industrial filters such as welding filters, pleated air filters, panel filters, inlet-type filters, and more, we back the quality of our products with our expert custom service. Contact us at 519-886-0749 today to learn more.